Electric vehicle battery cooling systems play an important role in maintaining stability and optimizing vehicle performance. However, few people clearly understand this system and its importance. To help readers have a comprehensive view of the battery cooling system, Wuling EV Vietnam have compiled and introduced to you all relevant information below.

1. What is an electric vehicle battery cooling system?

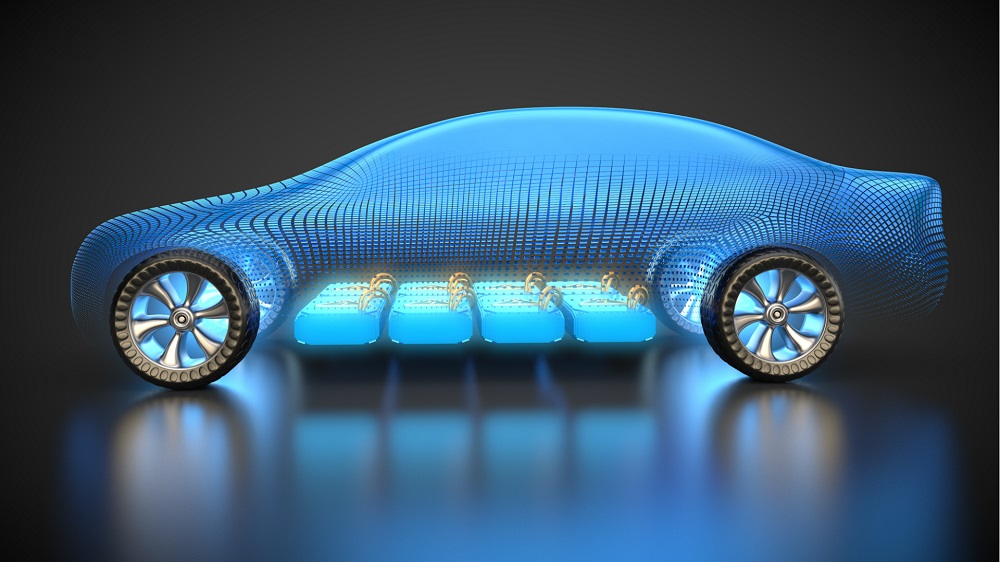

The energy of an electric vehicle is stored in the battery and transmitted directly to the engine when the vehicle is operating, chants for the battery to become the "soul" of electric vehicles and the core technology of this vehicle line. When the temperature drops below 0 degrees Celsius, the chemical reaction in the battery takes place slowly. This reduces the vehicle's power and acceleration as well as a higher risk of battery damage during charging.

However, batteries also tend to degrade quickly when operating at temperatures above 45 degrees Celsius. Batteries emit large amounts of heat to meet rapid chemical reactions. When the temperature is high, the battery consumes more electrical energy, and the engine is susceptible to overheating, creating a dangerous risk of fire and explosion. The electric vehicle cooling system plays an important role in helping the battery operate in the most ideal temperature range.

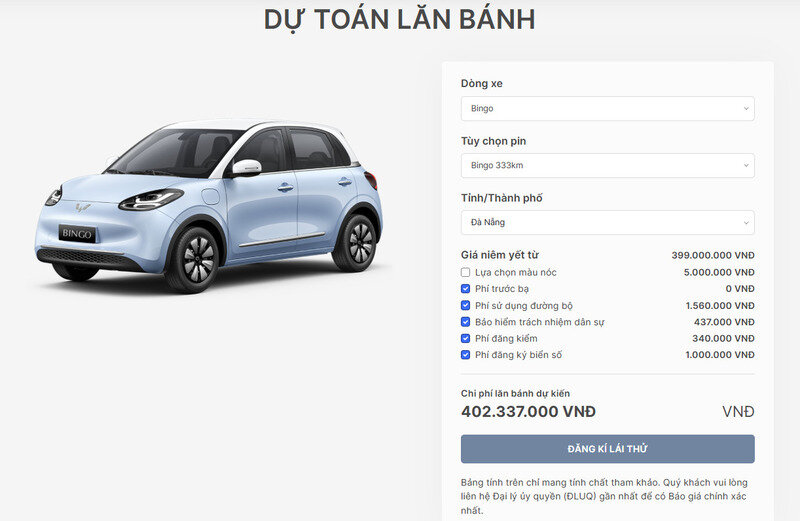

The cooling system helps optimize the performance of electric vehicle batteries

For the above reasons, the vehicle needs a cooling system to ensure the vehicle always operates stably. Electric vehicle battery cooling system Currently, ethylene glycol cooling solution is often used. This is a liquid, colorless and odorless organic compound that regulates temperature. This solution is circulated from the battery to the engine during vehicle operation. In addition, the system is also equipped with a radiator fan to help cool the engine effectively.

2. Classification of cooling systems

There are two electric vehicle battery cooling system's main types: passive cooling systems and active cooling systems. Passive cooling systems use methods such as using phase change materials, heat pipes or chemicals for cooling. Meanwhile, the active cooling system is based on the operating principle of radiator fins, air or special coolant. Both methods improve cooling efficiency, naturally, Can be affected by external environmental temperature in some cases:

2.1. Cool the battery with phase change material

Phase change materials (PCMs) are special coolants whose main ingredients are carbon or hydrate salts. When the battery of an electric vehicle emits a large amount of heat, the PCM absorbs heat from the battery and changes from solid to liquid state or vice versa. This process allows the PCM to release heat energy to cool the battery.

The electric vehicle battery cooling system helps the battery operate efficiently

However, it should be noted that PCM phase change materials have a limited operating range, can only absorb heat at the location of the battery. Therefore, the application of PCM in electric vehicle production is still limited. Currently, PCM phase change materials are commonly used in "heat protection" for high-rise buildings in urban areas. However, with the development of technology, PCM research and improvement can open up the potential for widespread application in electric vehicle battery cooling system.

2.2. Cooled by heatsink

The radiator cooling method is also applied on electric vehicles. By creating airflow, the fins can reduce the temperature by contacting the air and dissipating the heat generated by the battery.

Cooling method by heat dissipation

However, the limitation of the heatsink is its large size, making the cooling system bulky and not widely used by electric vehicle manufacturers. Currently, the heat sink cooling method is commonly used in the production of electronic devices such as computers and laptops.

2.3. Cooling electric vehicles with liquid

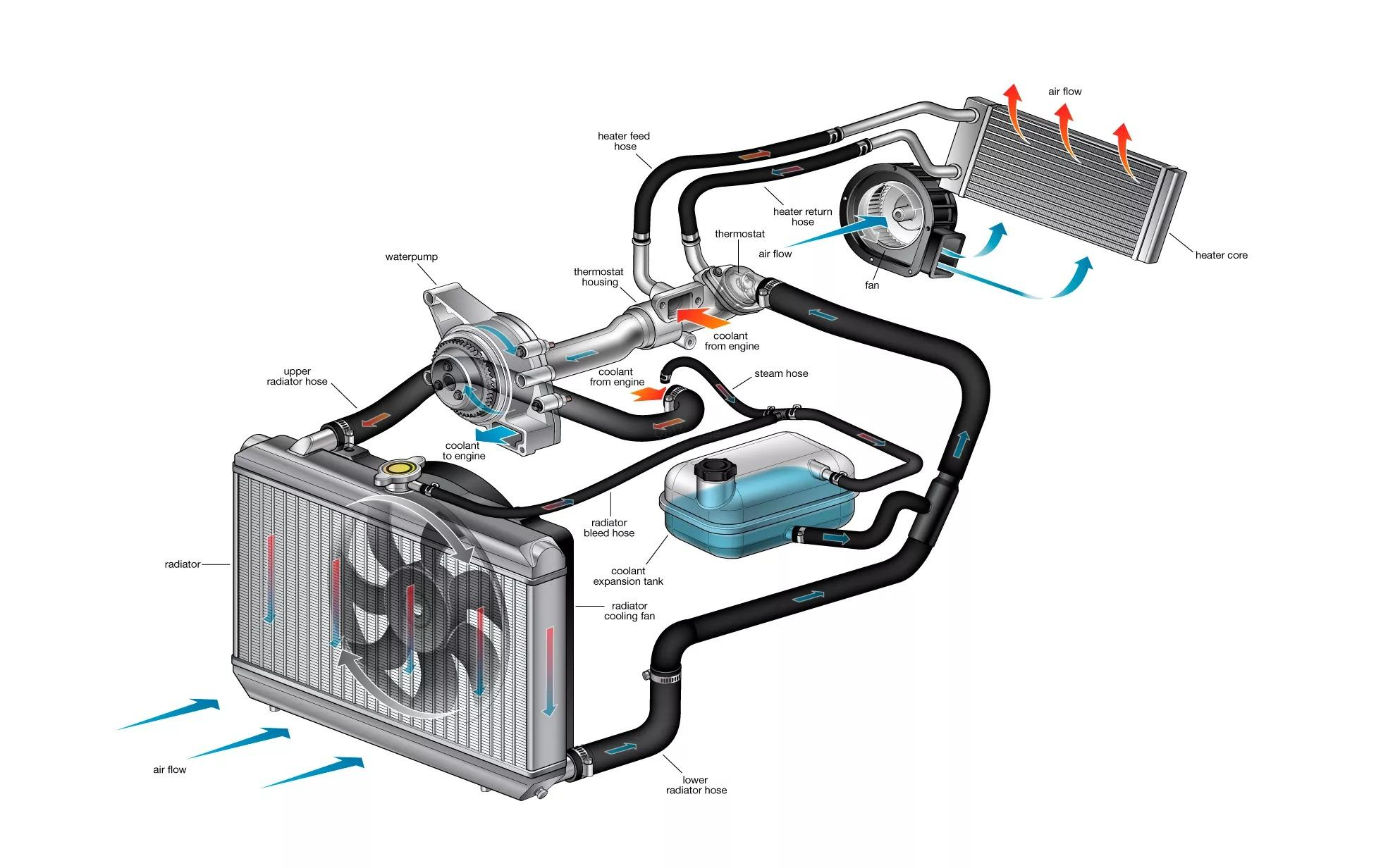

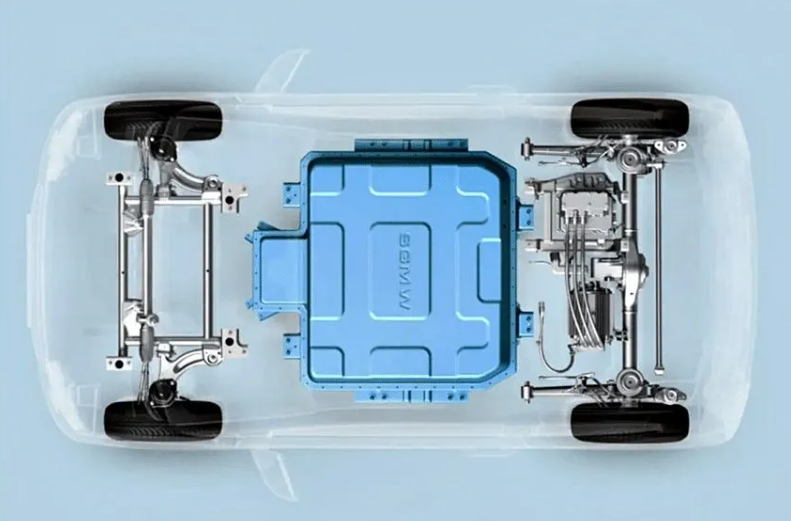

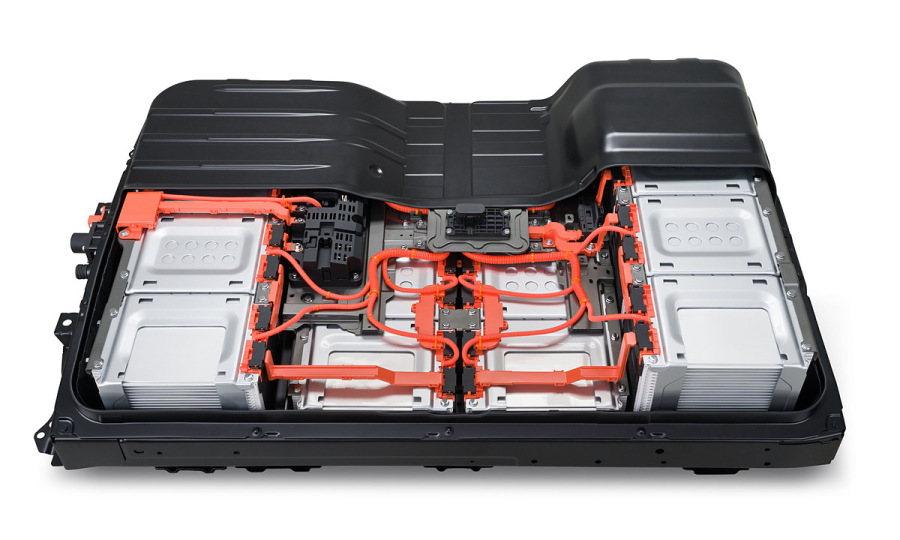

Liquid cooling is the most common method in electric vehicle battery cooling system. Compared with air cooling, this cooling system has more complex components. Companies have applied liquid cooling systems on electric vehicle models. On these models, the battery is cooled by a separate system, Completely separate from the engine's cooling system and other control systems. This is necessary because the operating temperatures of these components are different. Batteries must always be kept below 60 degrees Celsius, while motors and control systems can reach 140 degrees Celsius.

This cooling system works by passing coolant or water through tubes that run around the battery pack and other heat-generating components. The coolant absorbs heat from these components and then transfers the heat to other radiators or heat exchangers.

Liquid cooling method is widely used in vehicles

To operate, liquid cooling systems require pumps, fans, and other equipment. Therefore, this is considered a form of active cooling on electric vehicles, different from passive air cooling.

In addition to managing heat during driving, the fluid system also secures the battery during charging. Especially when using a DC charger for fast charging. The charging process generates heat, and fast charging causes even more heat, affecting the battery and charging wires/pins. Some cars have integrated coolant pipes directly on the charging cable to monitor temperature. If the system detects that the temperature exceeds the allowed threshold, the charging current will automatically decrease to protect the battery.

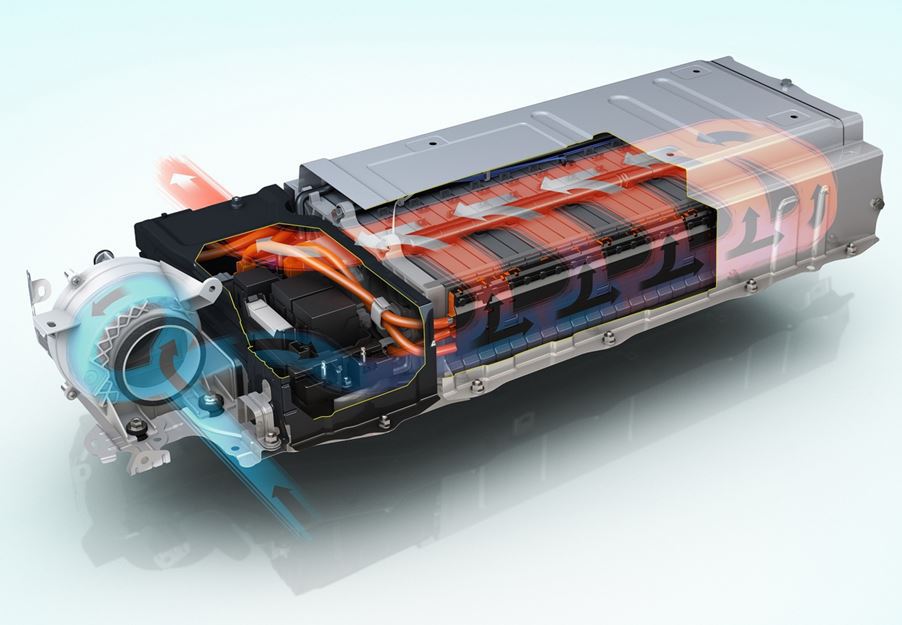

2.4. Thermoelectric cooling

Thermoelectric cooling systems (TEC) are highly appreciated by many manufacturers thanks to their modern design and effective heat reduction ability. The TEC system uses a total operating module consisting of two positive and negative terminals, attached directly to the battery. When operating, large temperature differences will be created. At this time, the module will convert heat energy into electricity, helping the battery maintain a temperature between 31 and 34 degrees Celsius.

Thermoelectric electric vehicle battery cooling system

2.5. Air cooling of electric vehicle batteries

Electric vehicle battery cooling system using air works quite similarly to the heat dissipation method. In this, it uses air convection currents to transfer heat away from the battery in an electric vehicle.

Air cooling systems use air convection currents to cool electric vehicle batteries

Wuling Mini EV uses an air battery cooling system

This method has an outstanding advantage: the operation process is simple and easy to control. However, this system is greatly influenced by the ambient temperature, leading to unstable cooling capacity and difficulty meeting requirements, especially when electric vehicles operate in hot weather conditions. Therefore, air cooling is not suitable for electric vehicles that operate frequently at high performance.

3. Some other elements of the cooling system

When designing an electric vehicle battery cooling system, in addition to considering the cooling solution, other factors should also be kept in mind. Those factors include:

- Size and shape of the battery pack: The size and shape of the battery pack will influence the design and selection of appropriate cooling components.

- Temperature sensing and control strategy: A reasonable control strategy is needed to maintain a stable battery temperature. Use temperature sensors to accurately monitor and control the cooling process.

- Coolant type and concentration: Select the appropriate coolant and ensure the coolant concentration is sufficient to optimize cooling and protect the battery.

- Location of heat exchanger and coolant pump: Place the heat exchanger and coolant pump in a suitable position to ensure cooling efficiency and optimize coolant flow.

- Cooling capacity and flow rate: Cooling capacity needs to be sufficient to ensure the battery operates at a stable temperature. The flow rate of the coolant is also important to ensure efficient heat transfer.

Other factors also need to be considered during the design of the cooling system

The above article is all information about electric vehicle battery cooling system. We hope that this content has helped you better understand battery cooling systems and will answer your questions. If you have any questions or want more detailed information, don't hesitate to contact us. Team of Wuling EV Vietnam always willing to support you and answer any questions. Let us accompany you on your journey to discover and better understand electric cars.